With 5G ready for commercial use, these PCBS and FPC materials are more popular

5G communication is a communication technology that relies on semiconductor materials and devices to realize long-distance transmission, transceiver and processing of wireless electromagnetic waves.

Compared with traditional communication technology such as 4G, 5G must be in accordance with full spectrum access, high frequency band and millimeter wave transmission, high spectrum efficiency three basic performance requirements, so raw material to the device is also put forward higher demand for performance and upgrade, such as large-scale integration, materials with high dielectric constant and low dielectric loss, and materials with high electron mobility, etc.

The 5G industry chain alone will reach $3.5 trillion in economic output and create 22 million jobs by 2035, according to IHS research.

More significantly, 5G will create $12.3 trillion worth of sales activity in multiple industries worldwide, accounting for 4% of the total global sales activity!

Which polymer materials are more popular in the 5G era?

TEFLON

Excellent high frequency PCB board material

High frequency pcb board manufacturer material performance requirements include dielectric constant (Dk) must be small and very stable, and as consistent as possible with the copper foil thermal expansion coefficient.

At the same time, water absorption should be low, otherwise affected by moisture will affect the dielectric constant and dielectric loss.In addition, heat resistance, chemical resistance, impact strength, peel strength must be good.

Thermoplastic material PTFE has the characteristics of high temperature resistance, operating temperature up to 250℃.The dielectric constant and dielectric loss in a wide range of frequency are very low, and the breakdown voltage, volume resistivity and arc resistance are high, is an ideal printed circuit board material.

PTFE can also be strengthened through various forms of fillers such as glass fiber or ceramic materials and can improve the thermal expansion coefficient of the material. The material has the low temperature characteristics and electrical characteristics of PTFE itself, which is very suitable for the application of high frequency millimeter wave multilayer plate.

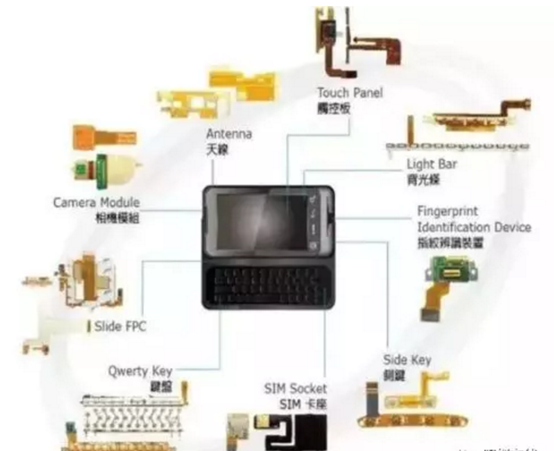

Mobile phone antenna

LCP liquid crystal polymers are a new facorite

As an important link of wireless communication, antenna technology innovation is the key power to promote the development of wireless connection.With the approaching of 5G and the large-scale deployment in the era of Internet of things, the role of antenna in 5G network will become more and more important, and the development prospect will also be promising.

Taking smart phones as an example, due to the development of the industry and the market, with the integration and high integration of the appearance design of mobile phones, the internal space is constantly reduced, which can be said to be extremely difficult for antenna design.

Mobile phone antennas have evolved from an early external antenna to a built-in antenna, and flexible panels have become a mainstream technology, with more than 70%.

At present, the soft plate substrate of mobile antenna is mainly PI, but in view of the large dielectric constant and loss factor of PI substrate, high moisture absorption, high frequency transmission loss and poor structural characteristics, PI substrate cannot well meet the requirements of 5G for material performance.

With the advent of 5G technology, LCP (industrial liquid crystal polymer) has become an ideal antenna material.It is a new type of high performance special engineering plastics developed in the early 1980s.

LCP has excellent electrical insulation performance, higher dielectric strength than general engineering plastics, good arc resistance. Even if the continuous use temperature 200-300℃, will not affect its electrical performance. Intermittent use of higher temperature up to 316℃ or so!

Compared with PI, LCP materials have lower dielectric loss and conductor loss, and are more flexible and hermetically sealed. Therefore, LCP materials have a promising prospect in manufacturing high-frequency devices.With 4G moving towards high frequency and high speed 5G network, LCP is also expected to become a new soft plate technology to replace PI.

MPI modified polyimide

5G mobile phone antenna material rising star

LCP, as a mobile phone antenna material, has many advantages, but it also faces many challenges in practical application.

So what is MPI? Modified PI is a Modified polyimide antenna. As an amorphous material, MPI has a wide operating temperature and is easy to operate under low-temperature pressed copper foil, and its surface can be easily connected with copper. Therefore, MPI material may also become a popular material for 5G equipment in the future.

Radome

A variety of resin substrates are used

As 5G antenna follows the concept of MIMO (Multiple Input Multiple Output), which means Multiple Input Multiple Output, it means that Multiple antennas can be installed in a base station, and the size of these antennas is small, which requires the protection of radome.

The radome should have good penetration characteristics of electromagnetic wave and be able to withstand the erosion of external harsh environment such as storm, snow and ice, sand and solar radiation.

In terms of material requirements, it is required that the dielectric constant and the tangent of loss Angle should be low under working frequency and that the mechanical strength should be sufficient.

In general, inflatable radome commonly coated with hypalon rubber or neoprene rubber polyester fiber film;Glass fiber reinforced plastics for rigid radome;A honeycomb core or foam is used in the sandwich structure.

Under the trend of 5G, the composite material with superior performance becomes a popular antenna cover material.Composite materials can play the role of insulation, anti-corrosion, lightning protection, anti-interference, durability and so on, and the transmission effect is very good.

The composite material is composed of reinforced fiber and resin matrix. Generally, the mechanical properties and dielectric properties of the reinforced material are better than that of the resin matrix. Therefore, the permeability of the composite material mainly depends on the properties of the resin matrix.

Therefore, it is very important to choose the resin matrix with excellent electrical properties, and the resin also plays the role of adhesive in the composite material, which is the basic component that determines the heat resistance of the composite material.

The main selection of resin matrix includes:

The traditional unsaturated polyester resin (UP), epoxy resin (EP), modified phenolic resin (PF) and cyanate ester resin (CE), silicone resin, bismaleimide resin (BMI), polyimide (PI), polytetrafluoroethylene (PTFE) and other new high temperature resistant resins have been studied and applied in recent years.

PC and PMMA plastic composite materials

5G era of mobile phone cover choice

In the age of 5G, more stringent requirements are put forward for materials of 5G application equipment. Since 5G travels at a metal-sensitive millimeter wave, using a metal case would mask the signal. Take mobile phone materials as an example, the metallization of 5G has become a trend.

The trend of the use of non-metallic materials such as glass, ceramics and composite plate, for example, plastic composite materials with superior performance, become the trend of the choice of mobile phone back cover.

Among them, the most popular number of PC/PMMA composite plate.The material is PMMA and PC by coextrusion (non-alloy material), including PMMA layer and PC layer.

PMMA layer after hardening can reach more than 4H pencil hardness, to ensure the product's scratch resistance, and PC layer can ensure that it has enough toughness, to ensure the overall impact strength.

Graphene

Idea material for heat conduction and heat dissipation of 5G equipment

High frequency, upgrade of hardware components and the number of connected devices and antennas have multiplied. Electromagnetic interference between devices and within devices is ubiquitous. Electromagnetic interference and electromagnetic radiation harm to electronic devices is also increasingly serious.

At the same time, with the upgrading of electronic products, the power consumption of equipment is increasing, and the calorific value is also rising rapidly.

In the future, high frequency and high power electronic products should focus on solving the electromagnetic radiation and heat generated by them.

For this reason, more and more electromagnetic shielding and heat conduction devices will be added in the design of electronic products.As a result, the role of electromagnetic shielding and cooling materials and devices will become increasingly important, and the future demand will continue to grow.

Taking thermal conductive graphene as an example, 5G mobile phones are expected to adopt customized thermal conductive graphene solutions in more key parts and components, while composite and multi-layer thermal conductive films will be more adopted due to their better heat dissipation effect.

The material industry has also ushered in a new era of 5G. Hardware carriers such as application phones, base stations, the Internet of things and automobiles will have more demands and higher requirements for 5G new materials.