[PCB Design] Design Check Rules can Reduce the Repeated Design of Circuit Board

Due to small problems such as signal integrity (SI), power supply integrity (PI) and electromagnetic interference (EMI), it is usually necessary to repeatedly design PCB, and the average cost of each repeated design is close to 28000 US dollars, so as to ensure that the generated design meets the mandatory requirements of its performance, time to market and cost objectives. In order to help eliminate complex and difficult to diagnose layout violations, some PCB design software tools will provide unique electrical design rule checks (DRC).Due to small problems such as signal integrity (SI), power supply integrity (PI) and electromagnetic interference (EMI), it is usually necessary to repeatedly design PCB, and the average cost of each repeated design is close to 28000 US dollars, so as to ensure that the generated design meets the mandatory requirements of its performance, time to market and cost objectives. In order to help eliminate complex and difficult to diagnose layout violations, some PCB design software tools will provide unique electrical design rule checks (DRC).

When using DRC analysis as an integral part of PCB design process, engineers can ensure that their PCBs meet the constraints of various high-level electrical design rules. DRC tools include customizable signal integrity (SI), power supply integrity (PI), electromagnetic interference (EMI) and safety rule inspection, so that designers can quickly identify and correct violations before starting the manufacturing process Behavior, by running DRC analysis, can remove the error prone manual inspection, reduce the expensive cost of repeated design, and then speed up the time to market, enhance the profitability of the company.

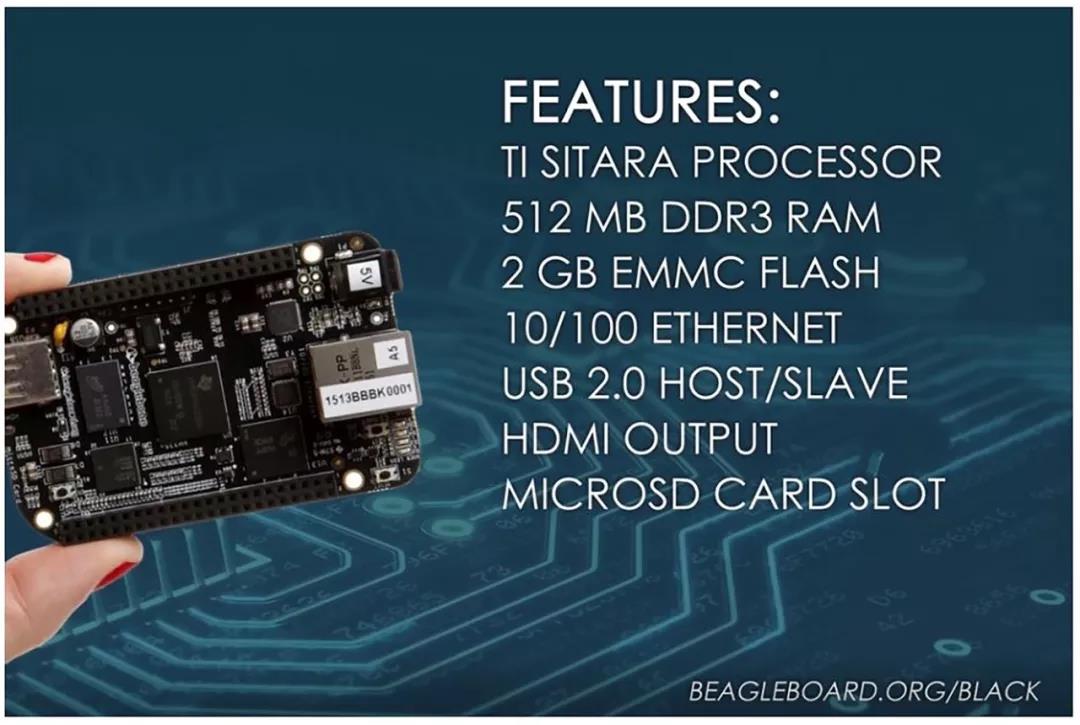

In order to illustrate the powerful advantages of using PCB design tool with close integration DRC analysis function, we will take the beaglebone black computer as an example. Beaglebone black is a low-power, open-source single board computer produced by Texas Instruments (TI). Developers and amateurs often use this kind of computer. The development board is composed of Ti Sitara processor, which provides the guarantee of performance, power consumption and peripherals, helps to reduce the system cost, simplify the design and expand the connectivity in the overall beaglebone black design. In addition to Ti Sitara processor, the circuit board also includes 512MB DDR3 ram and 2GB flash memory as well as many physical interfaces and other functions.

Figure 1: beaglebone black is an open source development board, package Integrated DRC and PCB layout Interface

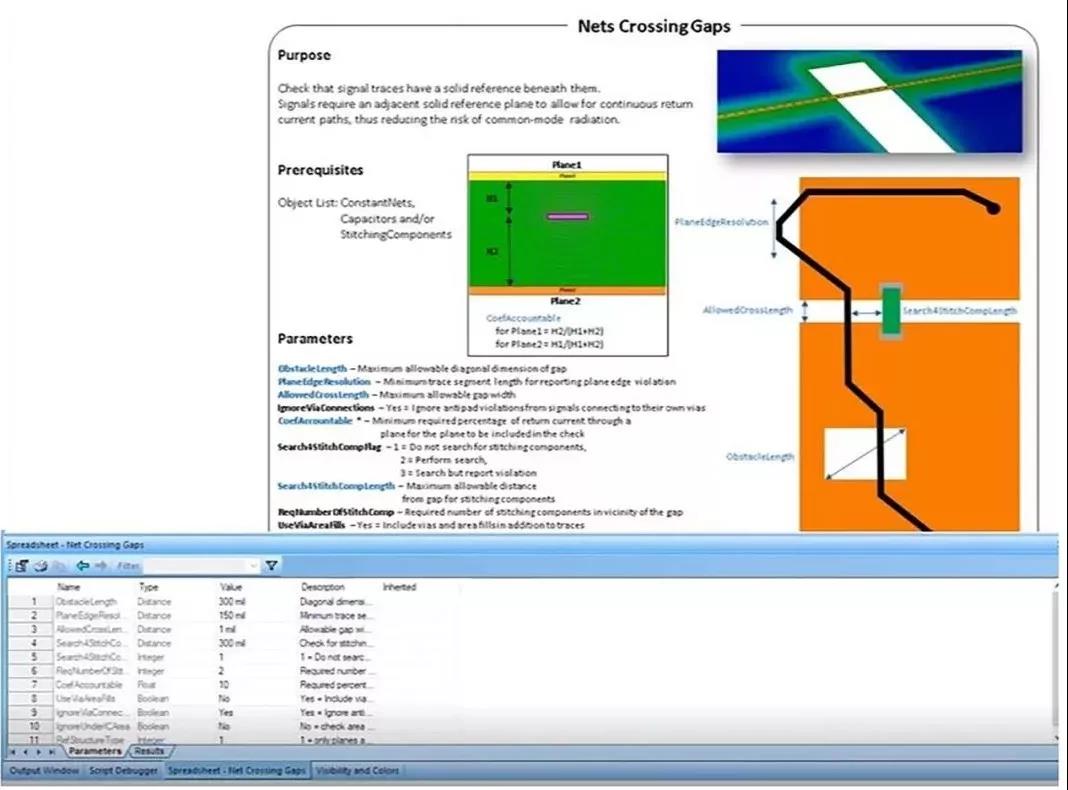

Due to the complete integration of layout and DRC tools, PCB design can be directly loaded into DRC from PCB layout window. The rules in DRC are specifically divided into Si, PI, EMI and security classes. Each individual rule contains a descriptive overview page that allows designers to easily choose the most important tests to run on their PCB layout. Figure 2 shows an overview page of the network cross clearance rules in the DRC.

Figure 2: overview page of network cross gap in DRC tool, including brief description, graphic image and descriptive parameters

When the high-speed network passes through the partition plane, the signal line will produce impedance discontinuity, which may lead to unwanted reflection, radiation and crosstalk. With the increasing complexity and density of today's PCB design, it is a heavy manual process to find and review all instances of a mesh passing through a split face. In addition, standard simulation tools usually do not check, when running the network cross clearance rule in DRC, it is easy to accurately determine the possible impedance discontinuity.

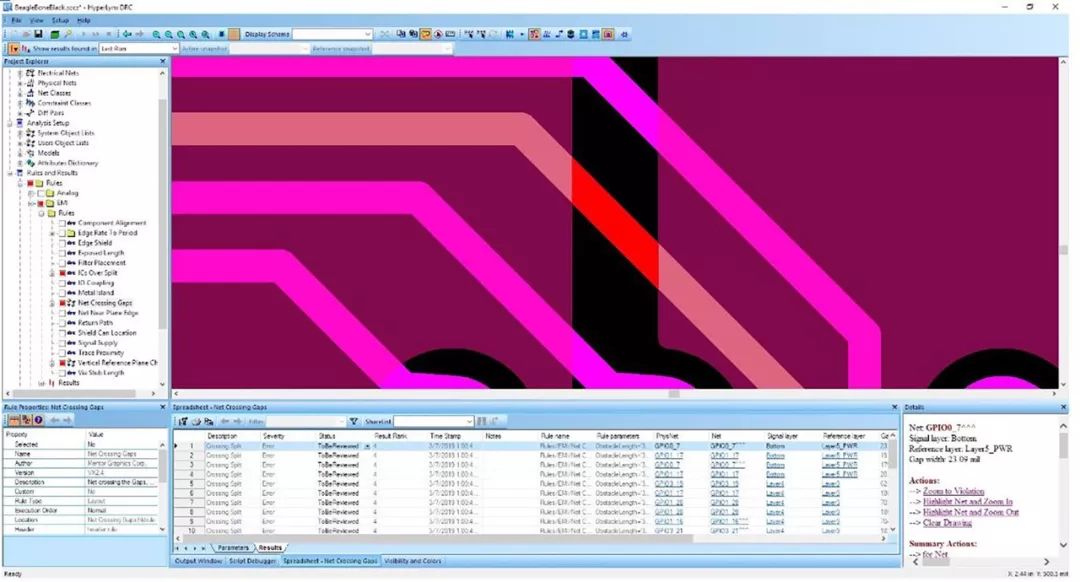

After running the rule, the designer can select the spreadsheet option to display the test results. By clicking a specific violation event in the grid option, the tool will jump to the exact location of the error in the PCB design (Figure 3), highlighting any components or wiring associated with the violation.

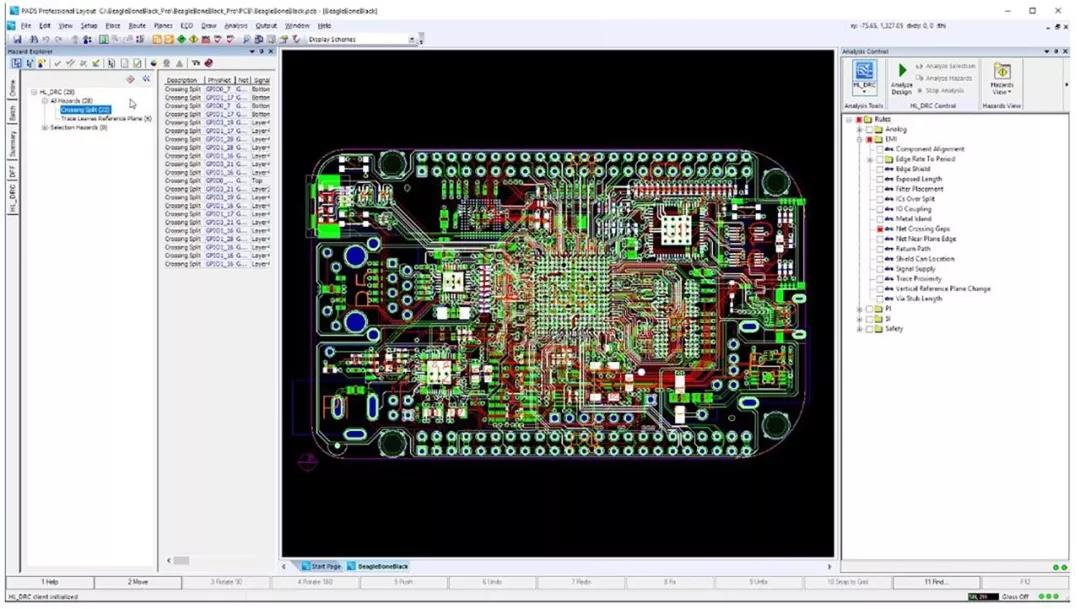

Figure 3: when selecting an instance of violation rules, DRC tool will be able to scale the violation positions in PCB design in the window through the closely linked layout and DRC interface, and the violation data from DRC customers will be automatically loaded into PCB layout tool, so that the designer can easily make any necessary changes to its layout without any manual cross reference between tools, to ensure that the design To clear violations after making changes, you can use the linked DRC client to run or rerun any selected rules directly in the layout tool window, as shown in Figure 4.

Figure 4: the integrated DRC client can be displayed inside the PCB layout tool. Once the PCB change is completed, the client can easily run or rerun the rules

Through closely related PCB layout and DRC tools, designers can ensure that their PCB will not fail due to neglected signal integrity (SI), power integrity (PI), electromagnetic interference (EMI) and safety violations. The editable parameters in DRC allow users to fully control to make each test adapt to its specific design requirements. According to this, in addition to more rules, DRC can also guarantee the China PCB manufacturer that their PCB can work normally, while reducing board failure and repeated design. When the design meets the expectations of all the advanced electrical rules of the front end, PCB board manufacturer can speed up the time to market of products and ultimately improve the profitability.